Product

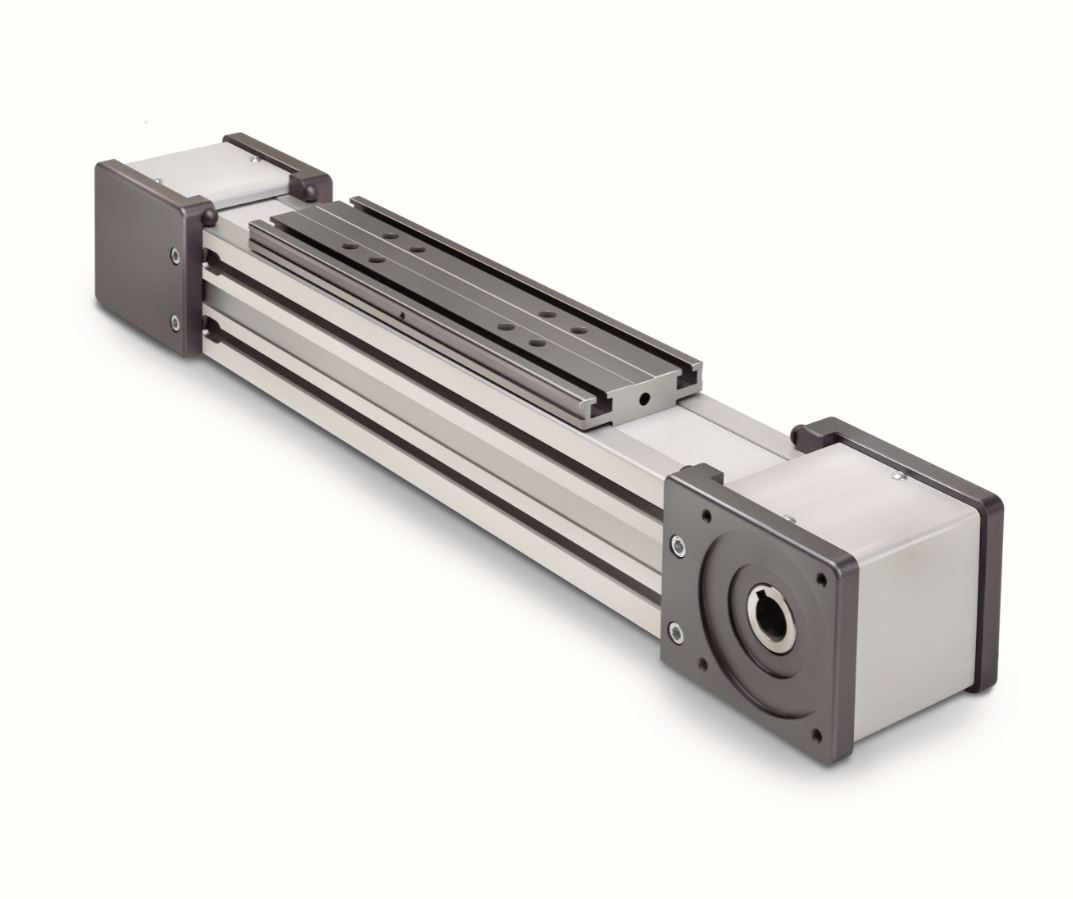

Module linéaire AGORA Technique

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

Ball screws for low speed and precise positioning These ball screws are used in applications in which high accuracy and low speed of positioning are required. They are suitable especially for precise machine tools. The shaft thread is generally ground. These ball screws are only available with double preloaded nuts AP+A, or A+A. The ball screws are offered in IT1 precision class and for their maximum thread length the following formula should be kept: Lz = 20×Do. The load capacities of these ball screws are reduced to 70% of the load capacity of standard ball screws due to the reduction of the number of balls in the nuts. The main advantages of these ball screws are their high accuracy and smooth run. Furthermore their high flexibility allows the production of ball screws exactly according to the customer’s needs. For this type of ball screws the following nut types are available: Double preloaded nuts Characteristics: Precise ground positioning screws with IT1 precision class Standard geometric and working accuracy according to DIN ISO 3408 Reduced tolerance of Tp values (usually by 10 to 15% compared to the standard) Delivered with customized preloadTechnical parameters: Diameters from 20 to 80 mm Recommended pitches 5 and 10 mm, thread lengths to 20×Do Precision class IT1 Do×n = 80,000, efficiency 94–97% (according to thread pitch and lubricant) Minimum strength of the shaft material Rm= 650MPa, functional surfaces of the shaft and nut hardened to 58-60HRC Working temperature -20 to +60°C (according to lubricant type) Lubricants with increased resistance to unstable high pressure are recommendedApplications: Precise machine tools – grinding machines, EDM and laser machines These ball screws do not have a separate technical parameter table and are delivered as customized solutions with respect to the limitations mentioned above. Example of designation: K40x5 – 4+4/AP+A PP/2 (ball screw with diameter 40 mm, with pitch 5 mm, 4 working threads, preloaded double nut AP+A, precise positioning design, flange type 2) Ball screws for low speed and precise positioning : www.ks-kurim.cz/en/ball-screws/ball-screws-for-low-speed-and-precise-positioning/

-

Consultations and technical advice KULIČKOVÉ ŠROUBY KUŘIM, a.s., offers technical assistance in designing and inspecting motion axes for machine tools equipped with ball screws. This service builds on long-term experience with the application of ball screws and calculation algorithms based on the DIN ISO 3408 international standards for ball screws, as well as cooperation with the Research Centre of Manufacturing Technology of the Czech Technical University in Prague. The objective is to identify and offer to the customer the optimum solution to linear movement based on a ball screw as the basic component for transforming rotary movement to linear. The optimization outcome is a specific actuation design using the most appropriate ball screw characterized by its diameter, lead, nut rigidity and service life, including alternatives employing either a driven shaft or a driven nut. The outcome can be expanded to include a choice of bearings, clutch, motor and embedded transmission, and the effect of actuation control. We also review the maximum speed and buckling of the ball screw designed based on its mounting. Based on the known range of loads and working conditions, we can determine the service life of the actual ball screw and its mounting bearings with the requested degree of reliability. The service offered should help design linear axes of machine tools with the objective of optimizing them based on expected loads and working conditions. Consultations and technical advice : www.ks-kurim.cz/en/services/consultations-and-technical-advice/

-

Transport ball screws Transport ball screws are used in applications where high accuracy of positioning is not required, such as for example in transporting and lifting devices, wood processing machines, etc. The screw shaft is produced by rolling or whirling and the shaft ends are machined according to the request of the customer. They are equipped as a standard with an APE type of nut, which is a single non-preloaded nut with flange. These ball screws are produced in the T5 and T7 precision classes. Their main advantage is a lower price. Characteristics: Productive and quick production of the screw Non-preloaded nut with backlash 0.015–0.05 mm (depending on the ball screw size) Standard geometric and working accuracy according to DIN ISO 3408 for transport ball screwsTechnical parameters: Diameters from 12 to 63 mm – rolled, from 32 to 100 mm – whirled Recommended pitch up to 10 mm – rolled and up to 30 mm – whirled Precision class T5, T7 Do×n = 80,000, efficiency 93–95 % (according to thread pitch and lubricant) Minimum strength of the shaft material Rm = 650MPa, functional surfaces of the shaft and nut hardened to 58-60HRC Working temperature -20 to +60°CApplications: Transporting mechanisms Wood processing machines Substitution of racks Long actuation assemblies Example of designation: K63x10 – 4/APE TS (ball screws with diameter 63 mm and pitch 10 mm, 4 working threads of the APE single nut with flange, transport design, the standard type 3 of the flange is not pointed out). Transport ball screws : www.ks-kurim.cz/en/ball-screws/transport-ball-screws/

-