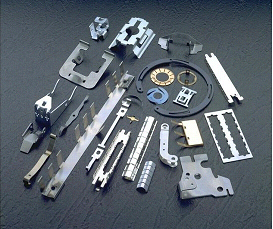

Product

TRANCIATE

Filo da: 0,20mm a 10mm

Macchine utilizzate: (fino a 160 Ton.) Manzoni, Zani, Gaiani, Dellavia, Sangiacomo

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

Torsion springs in 1600 spring sizes for fast delivery from stock made of stainless steel EN 10270-3-1.4310 from Gutekunst. The torsion springs are made of round spring steel wire in a cylindrical shape with tangential straight legs and a linear spring characteristic in quality grade 2 (medium tolerance range) according to DIN EN 15800. The torsion springs are offered in the leg positions 0, 90, 180, 270 degrees and in the left and right winding direction. Simply select the right torsion spring in the spring shop and order it directly from Gutekunst using the shopping cart. CAD data, data sheets and spring characteristic diagrams are available for each torsion spring.

-

Material: Piston rod and pressure tube steel. Fill medium: oil, nitrogen. Version: Piston rod, hard chromed. Piston rod Ø4 is stainless steel. Pressure tube painted black. Note: Gas springs are maintenance-free, self-contained systems that are filled with nitrogen under high pressure. For end-of-travel damping and lubrication, a defined amount of oil is also contained inside. The gas springs contain a nonreturn valve in a threaded pin on the pressurised pipe, which allows the pushing force to be lowered at a later time. As of size 08/19, storage and installation in any orientation is possible. Keep in mind, however, that end-of-travel damping is effective only when the piston rod extends downwards. As a consequence of the physical properties when filling a gas spring, a tolerance range of ±5% results for the rated pushing force. Gas springs are filled with nitrogen under high pressure and under no circumstances should they be opened or overloaded.

-

We only produce in accordance with customer specifications. Compression springs can assume a wide variety of designs and forms. Our production facilities include compression springs with wire thicknesses in the range of 0.30 to 3.00 mm with abraded ends and in the range of 0.10 to 4.00 mm with unabraded ends.

-